|

|

ModuMaid Covid Robots for Safe Classrooms

The ModuMaid-Air and ModuMaid-UV are autonomous disinfection robots developed in collaboration with Mechanical Engineering,

Tsignhua University, National Autonomous Univerity of Mexico, and RPI to disinfect both human-free and human-occupied spaces safely and efficiently.

|

|

|

|

|

SuperBaxter, a collaboration with the former Rethink Robotics

SuperBaxter is a next-generation collaborative bi-manual robot with enhanced human/robot interface and Barrett Hand grippers

with force and tactile sensors, including SynTouch.

|

|

|

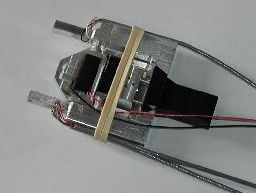

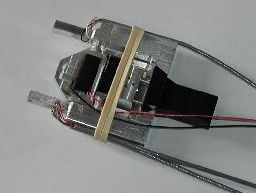

Precision micro-gripper with tactile sensing and high dynamic range motion control. The gripper can grab things on the scale of millimeters

and position them within tens of nanometers of accuracy (under temperature-controlled conditions), spanning 5-6 orders of magnitude.

Robotic Systems

Robotic Applications

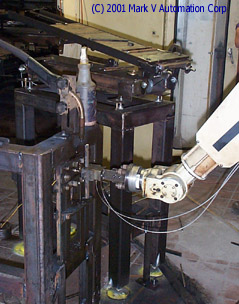

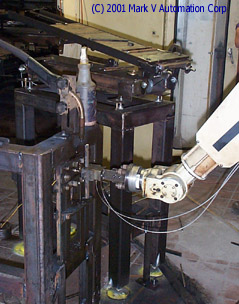

Olin Wrought Iron is a local wrought iron shop that primarily makes standard

component parts for other craftpeople to construct custom decorative railings

and gates.

These components are exported all across the country and the world and, as a

result, Olin Wrought Iron must compete with other international suppliers

from countries with very low labor costs. Prof. Voyles worked with Olin

Wrought Iron to develop this robotic welding application to perform

high-volume welds with very low capital and recurring costs.

|

|

|

The robot above is a surplus PUMA 760 retrofitted with a set of control cards

that resulted from Prof. Voyles' research.

|

The picture above is a close-up of the robot inserting four square bars into

the welding fixture.

|

The robot above is a surplus PUMA 760 retrofitted with a set of control cards

that resulted from Prof. Voyles' research. Prof. Voyles' company,

Mark V Automation Corp, supplied the boards and software, Prof. Voyles

set up the initial application, and Olin employees built the fixtures and

programmed the movements.

The robot has been a great success for Olin Wrought Iron. It requires

very little attention (only the feeder needs loading twice per day),

has very high yield, and frees up skilled welders from a boring, repetitive,

low-skilled task. This project is a perfect

example of how University expertise can impact the local community. Research

hardware and software was applied to a real-world application, via University

expertise, to economically build an automated system to keep a local employer

competitive in the world marketplace.

rvoyles [at] purdue [dot] edu