Some Current Research Topics

We have a wide range of topics that change with time. Typically, a Ph.D. student will work in a couple related topical areas. Much of our research focuses on national defense or energy related areas. Most is experimental, but we do have some computational and theoretical work.

- Nanoscale Propellant Ingredients. Nanoscale metal fuels (e.g. aluminum) and ultra-high surface area catalysts promise improved performance over conventional ingredients in composite solid propellants, however there are undesirable consequences of simply replacing conventional metal fuels with nanoscale counterparts. For example, the addition of nanoscale particles can lead to poor rheology of the propellant mix, unacceptable final mechanical properties, and nanoscale aluminum can readily sinter as it is heated. We are exploring approaches that include encapsulating nanoscale particles within micrometer scale crystalline components, fabricating micrometer sized particles with nanoscale features, and considering multicomponent metals such as alloys that can lead to droplet microexplosion shattering or dispersive boiling.

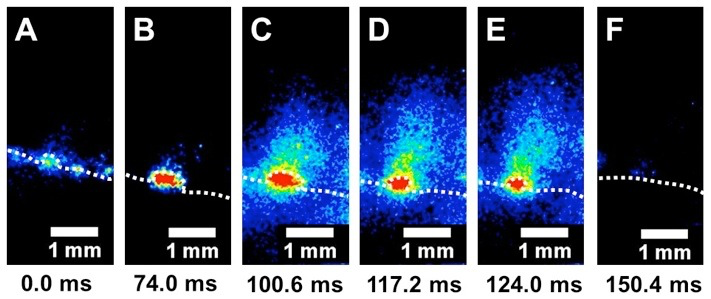

- Hypergolic Hybrid Propellants. We are developing novel measurement techniques for the study of heterogeneous reactions during combustion using in-situ time resolved spectral emission 2D topographical temperature measurement of a burning fuel surface will also be developed using laser-induced phosphorescence of embedded particles providing continuous temperature measurements of the surface for the first time in solid fuel. Experiments are planned to identify the mechanisms and chemical reactions that may allow hypergolic oxidizer/solid fuel combinations to exhibit high, pressure dependent, fuel regression rates necessary for eventual application to hybrid rocket technology. Amine boranes are compounds that exhibit highly hypergolic behavior yet have not been implemented in hybrid rockets. New variations of these amine boranes will be synthesized and used with metal-organics and metal hydrides as additives to fuel binders to provide highly reactive fuels, while gaseous oxygen and white fuming nitric acid (WFNA) will be used for standard and hypergolic combustion respectively.

- Shear Impact Initiated Reactives. Metal-based reactive composites are high energy-density materials that have potential uses as multifunctional energetics. However, when composed of micron size particles they can be difficult to ignite and have slow reaction rates. Recent work has shown that mechanically activated (MA) materials can have increased ignition ensitivity and reaction rate, yet the role of microstructure refinement (i.e., mechanical activation duration) in controlling combustion behavior is not well understood. We are fundamentally exploring these gaseous reactives that may eventually have application to reactive structures or bullets.

- Hot-spots (Energy localization) in Explosives. This research program seeks to develop a detailed understanding of the formation mechanisms and dynamics of localized energy dissipation known as hot spots from shock, impact or acoustic insult. The essential physics to be captured is the real-time visualization of the dynamic evolution of deformation and temperature fields at the size scales and temperature ranges of hot-spot formation under impact and periodic loading conditions. We are developing unique dynamic experimental methods to visualize the dynamic strain and temperature field evolutions focusing on and around an energetic crystal.

- Chemical Decomposition in High Energy Density Materials Induced by Coupled Acoustic and Electromagnetic Energy Insult. The nonlinear mechanisms by which energy input via the long wavelength vibrational modes of a high-energy density material (HEDMs) is transferred into localized, high-frequency modes that can initiate chemistry remains a key unsolved challenge at the boundaries of condensed matter physics, chemistry and materials science. Not only is the role of defects and heterogeneities in focusing energy into high frequency modes not well understood for high energy density materials, but also the fundamental role the piezoelectric nature of such materials can play in energy localization remains unexplored. Consequently, the ability to make use of such phenomena for detection, defeat, or material optimization is currently unrealized fully. The main goal of this work is to develop an understanding of how low energy (acoustic and electromagnetic) insults can induce localized chemical response.

- Characterization of Cocrystal Energetic Materials. The development of completely new molecules takes years of effort and unfortunately after such efforts the vast majority of promising molecules fail because of a few unacceptable properties. This work aims to develop the science and technology to take a new path to reach these goals, while building on the existing investment in molecular synthesis. For example, a current IHE that has low performance could be potentially cocrystalized with a higher performing, but too sensitive molecule, to yield a next generation IHE that has greatly improved performance compared to the original IHE and sufficiently low sensitivity. Our focus is to characterize the sensitivity, deflagration and detonation of newly developed cocrystals (a crystal made up of two or more molecules), typically with minimal amounts of material to direct the synthesis efforts toward more viable materials.

- Small-scale Characterization of Homemade Explosives. Terrorists increasingly use homemade explosives (HMEs) because of low-costs and availability. The specific compositions of HMEs are nearly limitless so making accurate simulations of the threat from these materials is challenging. Consequently, there is significant interest in quickly characterizing HMEs so threats can be more accurately modeled. In this work we have developed an experiment that requires only a few grams of material involving a transient detonation failure. A microwave interferometer is used to continually track the position of the transient reactive wave and shock wave, providing detailed data relatively quickly and at lower cost than alternatives.

- Shock Induced Combustion Synthesis of Cubic Boron Nitride. A meteorite impacting the Earth generates high pressures and temperatures. Sometimes such dynamic events result in the formation of materials. We are trying replicate these conditions to create materials able to withstand extreme temperatures and possessing superior strength and unique electromagnetic properties. Specifically, we plan to find a new approach for shock-induced synthesis of a material called cubic boron nitride. The material has a crystal lattice structure similar to carbon's and could potentially exist in many forms. The hexagonal form corresponding to graphite is the most stable and softest among these forms and is used as a lubricant and an additive to cosmetic products. The cubic variety is analogous to diamond, and its hardness is second only to diamond's, but its thermal and chemical stability is superior. Our approach is to chemically synthesize the boron nitride ignited and pressurized by a shock. The data obtained is used to calibrate models developed by our DOE Center collaborators.

- Integration of Energetic Materials and MEMs. This project seeks to develop and implement smart microelectromechanical systems that combine a proven sensing capability with an integrated energetic materials, using processes such as ink jet printing. The proposed effort focuses on basic research questions such as: What materials are suitable for direct integration with functional MEMS and CMOS devices? What influence do material parameters have on the mechanical and reactive properties of energetic materials deposited via additive manufacturing? How much electrical energy is required to initiate combustion/reaction in a selectively-deposited energetic? And, can selectively-deposited energetics surgically disable key electrical or electromechanical components? By successfully addressing these key questions, this effort will not only enable a new generation, small, smart, and surgical security and access control systems, but, perhaps more importantly, develop a fundamental foundation of science related to the use of energetic materials in additive manufacturing based engineering solutions – a potentially game-changing advancement.

- Characterization of Fuels Containing In Situ Grown Aluminum Nanoparticles for Ramjets. Ramjet air-breating propulsion systems have several advantages in tactical applications compared to rocket systems, including significantly higher specific impulse and range, and better safety due to the lack of onboard oxidizers. Solid-fuel Ramjets have additional advantages compared to liquid-fueled Ramjets due to the higher density of the fuel, simplified design, improved handling and storage safety, and the ability to add performance-enhancing solids into the fuel grain. Combustible metal powders have the potential to increase fuel performance without negatively affecting safety and IM compliance. Aluminum powder is commonly added to solid propellants to increase Isp in rocket motors, but is problematic in Ramjet applications because of the greatly reduces residence time in the Ramjet motor, which leads to incomplete combustion. Synthesizing nanoscale aluminum directly inside binder fuels allows very small oxide free aluminum particles to be formed that could result in very short reaction times. Our contribution is to modify and characterize these materials developed by Helicon Chemical Company LLC for application to ramjets.

- High-Speed PLIF Applied to Solid Propellants. Ammonium perchlorate (AP) has been the primary oxidizer in solid propellants since the 1960s. Models of AP flame structure, which seek to make accurate a priori performance predictions, have advanced beyond what has been observed experimentally. Experimental studies of flame structure are needed in order to validate existing models and lead to improved models. We have applied high-speed planar laser induced fluorescence to solid propellants that allow us to visualize, for the first time ever, some of microscale flame structures in situ in a burning solid propellant. We are able to determine how modifications of ingredients affect the combustion, and provide detailed data for model validation.

Equipment and Facilities

Our labs are located at Zucrow Laboratories that has a long history in rocketry and propellants especially. We are on univerisity property, but are not on the main part of the campus. A key capability of Zucrow labs is that we span from molecules and particles to application scales (e.g., rockets). Here is a map to find us.

We have four test cells that allow remote operation of experiments, and three other labs that we use for hands-on work. Some of our work in collaboration with Bob Lucht is done in laser diagnostic labs in the ME building and at the High Pressure Lab at Zucrow Labs.

Major equipment available at Purdue includes: 1) Phantom v7.3 high-speed video cameras (both color and black and white) capable of capturing 500,000 frames/sec in burst mode and equipped with K2 optics for microscale photography; 2) Windowed pressure vessel (up to 6000 psi); 3) High speed data acquisition systems; 4) Professional digital video camera with microscopic and macroscopic optics; 5) Remote operation test cells; 6) Retsch planetary ball mill; 7) ResodynLabRAM mixer for propellant mixing, 8) Branson 450W Sonic Horn, 9) Electrostatic discharge (ESD) sensitivity tester; 10) Fragment chambers, 11) Pneumatic and Hydraulic Presses, 12) High-speed custom visible spectrometer VS100-C (Acquisition speed of each spectra: Minimum of 16 KHz, Wavelength range: Minimum of 750 to 1000 nm), 13) IR imaging (high speed), 14) Agilent Micro Gas Chromatograph (model #: MicroGC 3000, 15) TA

Instruments dual beam DSC/TGA, 16) Hirox digital microscope, and 16) IR spectrometer (Fast Infrared Array Spectrometer (FIAS), 160 wavelengths from 1.4 to 4.8 um, Scan frequency: 6250 Hz, Acquisition frequency of1320 Hz). Characterization facilities available at Purdue include but are not limited to the following: Hitachi S-4800 Field Emission SEM, Philips XL40 SEM with a Schottky FEG with EDS and EBSD, JEOL Analytical SEM with Backscatter Imaging, FEI-Tecnai TEM, 80-200 kV, high resolution imaging with sub-2.4 Å point resolution, Titan 80-300 kV Environmental Electron Microscope, Bruker D8 Focus XRD, Panalytical MRD X'Pert Pro High Resolution XRD, Veeco DI Dimension 3100 and D5000 Atomic Force Microscope, a variety of GC-MS such as the ELEMENT2 and Agilent 5975C GC/MS, and a suite of Olympus optical microscopes equipped with Paxit software.

Hypergolic Propellants Lab

Click here to see more on Hypergolic Propellant Lab.